How to use MINSLITE-O to purify oxygen from nitrogen to obtain high-purity nitrogen

High-purity nitrogen is widely used in electronics manufacturing, semiconductor manufacturing, food preservation, pharmaceutical industry, metal processing, scientific research and precision instruments. The purity of nitrogen directly affects the effectiveness of these applications.

Usually we use the pressure swing adsorption (PSA) process to separate nitrogen from the air, and then further purify other impurities in the nitrogen to obtain high-purity nitrogen. The purification of trace oxygen is a very important step. After high-purity nitrogen is used, it may be mixed with oxygen, reducing the purity of nitrogen. At this time, in order to recycle and use the nitrogen, we can remove the oxygen in it, thereby obtaining high-purity nitrogen at a low cost, which can save the cost of re-purchasing.

In fact, there are many ways to remove oxygen, both physical and chemical, but only chemical methods can remove trace amounts of oxygen. MINSLITE-O is a new type of chemical material that can deeply purify oxygen without producing any by-products. It is an important material for producing high-purity nitrogen.

MINSLITE-O is very stable at room temperature. When it leaves the factory, MINSLITE-O is in an oxidized state. Before deoxygenation, we will introduce hydrogen to convert MINSLITE-O into a reduced state. The reduced MINSLITE-O will be able to combine with oxygen to purify the oxygen element from the nitrogen without producing any by-products. After deoxygenation is completed, MINSLITE-O will be converted to an oxidized state. At this time, we can repeat the previous reduction work (which we call regeneration) and use MINSLITE-O intermittently for deoxygenation.

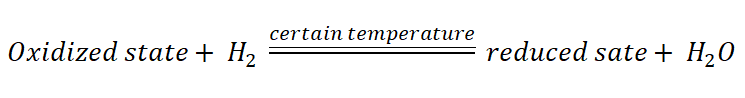

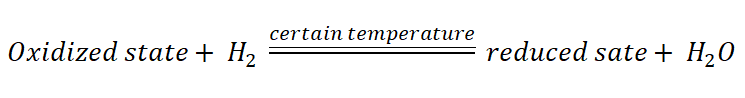

The following is the working principle of MINSLITE-O regeneration. This process is carried out at a certain temperature. MINSLITE-O will be reduced by hydrogen and discharge water.

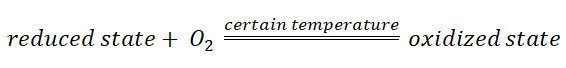

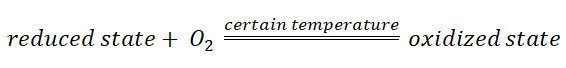

The following is the working principle of MINSLITE-O deoxygenation. This process is carried out at a certain temperature. MINSLITE-O will combine with oxygen and convert it into an oxidized state. This process does not produce any by-products.

Of course, in many cases, we need continuous deoxygenation. We can automate the equipment and achieve uninterrupted deoxygenation of MINSLITE-O by automatically switching between the two reactors.

The advantage of MINSLITE-O is that its operating temperature is not very high (about 300°C), and it can be reused continuously with almost no consumption, which will significantly reduce our operating costs.

If you need more information about MINSLITE-O, please contact Minstrong engineers at minstrong@minstrong.com and we will help you complete your project quickly.

minstrong

minstrong minstrong

minstrong